I am happy to say that Rockhopper v1.5 has repeated Rockhopper v1.0's win at Trinity! On my first run I got the perfect run of putting out both candles, found the baby, and went up and down the ramp to the second floor. This was something I was unable to do last year and I believe the first time this has been accomplished by any robot at this competition.

Things however went downhill from there. On my second run I hit the button to start and...... nothing. So this run was a bust. I took the robot back to my table and began to debug. It took some digging but I found it was just a bad connector. I was able to replace the bad wire and I _thought_ all was well.

I didn't have much time between when I thought I had fixed it and my next run. So, on my third run when I hit the button it _did_ move however very erratically as soon as I saw this I knew what the problem was. In the process of trying to figure out what was wrong I had disconnected my A/D connector so essentially the robot was completely blind. Worse actually because with the cable disconnected I just got random signals in place of my range sensors. So this run was a bust as well.

However my robot being the only one to accomplish any tasks was still by far the winner in the Expert divsison.

On to hide and seek.

Last year the expert divison was not eligible for the "Hide and Seek" competition. I just noticed in the rules about a week ago that this year it was open to all robots in the competition. The challenge in "Hide and Seek" is to find a baby in the maze. The baby is the same as in the expert division where they have a 15 watt light bulb painted black to simulate the body heat of the baby. The robot simply must find the baby and signify it has done so by either turning on an indicator light or (for a bonus) have an audible voice that it uses to say it has found the baby. I could not do the voice but the rest is the same thing as the robot already knows how to do from the expert division.

The robot gets 3 runs for this competition also. On my first run it found the baby but it signified that it found it outside of the 30cm limit so it didn't count. On my 2nd and 3rd run it found the baby both times but on the 3rd run it took quit a while so I didn't get a great score. Still, I figure 3rd place in an event I had not planned to do and never had any time to write special code for is pretty good.

So now, over the next week or so I plan on getting my thoughts down on paper with new ideas and such. I am also going to investigate what went wrong to try to avoid it next year.

Sunday, April 13, 2008

Friday, April 11, 2008

Greetings from Hartford

We just got to Hartford. The competition starts tomorrow! Well, technically tomorrow (Saturday) is for registration, practice and qualifying for the actual competition on Sunday but honestly Saturday is when all the fun is since that is when you meet other builders and see what they have done. On Sunday everyone is more concerned with the competition itself so there is less socializing.

I think I am in pretty good shape. Since my last post I have worked on improving the candle seeking and also added some code to re-find the candle when it looses sight of it. I also have it finding the "baby" fairly well however it is really sensitive as to the hight of the light bulb they use to simulate body heat. They do not specify how high off the ground it is but they do have a picture which I used to estimate it. Hopefully I can practice with the real thing some tomorrow.

I worked on it every evening this week also except last night (didn't get home from work until after 9:00). Most of this week has been working on some reliability code for recognizing when it is stuck. Last year I used wheel rpm to determine if the robot is stuck but this year I have tried a new method of watching the distance sensors. If it doesn't see enough variability in the distance sensors it assumes it is stuck and backs up a bit. From experimenting this seems to work well.

I also worked on some "intelligent" navigation code. OK, it isn't all that intelligent but should be an improvement over what I had last year. Last year it simply followed one wall for a while, then switched to the other wall. I found that it often picked a very inopportune time to switch so I have improved this a bit. First it only switches which wall to follow when in a hall. I realized last year that if it switches when in a room it is just going to go out the same way it came in and retrace the same steps. The other change is instead of switching after a specified amount of time it is watching the wheel distance sensors. If one wheel has turned considerably more distance than the other it thinks it might be in a loop. I set the threshold on this so it actually goes through the loop just over 2 times before it does this so it shouldn't do it too soon. I may tweak this setting some tomorrow as I experiment in the real maze.

The maze we get to practice in will not be the same layout as the competition but it should allow me to see how my code changes should work out in general. I plan on having Jane shoot some video as I run it through some simulated runs. I just realized I forgot my firewire cable so I won't be able to upload video until I get home but I do plan on posting some video of it on youtube or some place like that.

I think I am in pretty good shape. Since my last post I have worked on improving the candle seeking and also added some code to re-find the candle when it looses sight of it. I also have it finding the "baby" fairly well however it is really sensitive as to the hight of the light bulb they use to simulate body heat. They do not specify how high off the ground it is but they do have a picture which I used to estimate it. Hopefully I can practice with the real thing some tomorrow.

I worked on it every evening this week also except last night (didn't get home from work until after 9:00). Most of this week has been working on some reliability code for recognizing when it is stuck. Last year I used wheel rpm to determine if the robot is stuck but this year I have tried a new method of watching the distance sensors. If it doesn't see enough variability in the distance sensors it assumes it is stuck and backs up a bit. From experimenting this seems to work well.

I also worked on some "intelligent" navigation code. OK, it isn't all that intelligent but should be an improvement over what I had last year. Last year it simply followed one wall for a while, then switched to the other wall. I found that it often picked a very inopportune time to switch so I have improved this a bit. First it only switches which wall to follow when in a hall. I realized last year that if it switches when in a room it is just going to go out the same way it came in and retrace the same steps. The other change is instead of switching after a specified amount of time it is watching the wheel distance sensors. If one wheel has turned considerably more distance than the other it thinks it might be in a loop. I set the threshold on this so it actually goes through the loop just over 2 times before it does this so it shouldn't do it too soon. I may tweak this setting some tomorrow as I experiment in the real maze.

The maze we get to practice in will not be the same layout as the competition but it should allow me to see how my code changes should work out in general. I plan on having Jane shoot some video as I run it through some simulated runs. I just realized I forgot my firewire cable so I won't be able to upload video until I get home but I do plan on posting some video of it on youtube or some place like that.

Monday, April 7, 2008

Final full build day

The final full day I have taken a vacation day for is here. The competition is this weekend. I think I am pretty close to "done". Of course projects like this are only really done when you are out of time, there is always something that could be improved upon.

The final full day I have taken a vacation day for is here. The competition is this weekend. I think I am pretty close to "done". Of course projects like this are only really done when you are out of time, there is always something that could be improved upon.The general navigation is working well, better actually than the original Rockhopper from last year. The advantages v1.5 has is it is a few centimeters narrower and also the fact that the PWM control for the motors is running on the AVR which is more dedicated to the task which gives me finer grained control than running it on the ARM (Rockhopper v1.0 updated the PWM in the kernel timer interrupt at 100hz, the AVR updates it at 2khz).

I did run into a couple of major snags. I bought a couple of USB-i2c adapters and planned on using them to talk to the AVR board. It turns out the AVR i2c implementation has some latency issues and the USB-i2c adapter has a short timeout. The end result was the i2c adapter would time out before the AVR would respond. This seems odd considering the AVR implements this in hardware but the i2c adapter really needs a way to set the timeout. Unfortunately the adapters are not open source so I can't do anything about them. Sounds like I need to design my own open sourced USB-i2c adapters next year.

The fallback plan there was to use the serial ports on the ARM and AVR for communication. The fastest I seem to be able to communicate is 19200 baud. Any faster than that and I get too much error to be useful. Considering I am not sending a large amount of data between the 2 boards I expected this to be fine however this led to my next big issue... not throughput but latency.

The latency is so high (I don't have specific numbers but I wrote a test program to demonstrate it) that the robot becomes uncontrollable. The situation is this: AVR grabs sensor data (such as from the ir range sensors), ARM reads that value over the serial port, ARM decides it is too close to the wall and writes a new speed to the motors over the serial port... by the time all this happens we are even closer to the wall so on the next iteration it needs to turn even more abruptly... then suddenly we are poiting directly away from the wall and need to over compensate toward the wall.... The end result is it wildly veers toward and away from any obstacle and makes very little forward progress.

The fix for this was to implement all of the time critical stuff directly on the AVR. Programming the AVR is simple enough but it is much harder to debug than running on under linux on the ARM. However, most of these algorithms are essentially the same as I have used on several robots in the past so I wasn't starting from scratch. I ran into various snags on stupid little bugs that took considerable time but it is all working well now.

So, with less than a week to go where to I stand? Navigation (in the follow a wall and don't run into anything sense) is working well. It finds the candle fairly well but not as well as I would like (that is the highest priority for today). Once I get finding and blowing out the candle working well the next plan is to work on reliability. The thing that won the competition for me last year was the reliability, it simply _never_ got stuck. If it can continue to explore the maze it should just by dumb luck eventually find the candle.

Lowest priority just as last year is finding the baby and dropping the beeper (see rules for what I mean). I hope to be able to get this working as this is the one task that Rockhopper never quite did successfully last year and I really would like to get a perfect score on at least one of my competition runs.

Now, back to work....

Saturday, March 22, 2008

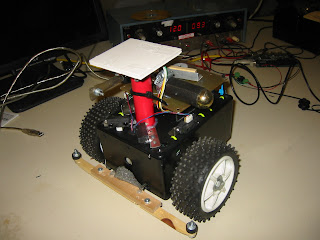

Rockhopper v1.5

As usual I have been bad about updating my blog. I have started on a new version of Rockhopper for this years Trinity College Fire Fighting contest. I certainly can't take 8 weeks off like I did last year but honestly the majority of that time was spent figuring out how to do things so by taking what I learned from that I should be able to do this one much more quickly. There won't be any major new ground broken with this one (which is why I call it v1.5 instead of v2.0) but it will be a "refined" version of last years design. Much of the code will be re-used from last year with some updates. I am using the same linux kernel as before also so that is a lot of time saved not having to re-do that.

The highlights:

It is smaller. Rockhopper was just barely within the maximum allowed size of 30cm (in all dimensions). Rockhopper 1.5 is about 22cm wide and long. This should make it able to maneuver past obstacles more easily.

Cleaner wiring. Since much of how I am doing things is the same as last year I know ahead of time what is going in. The problem with Rockhopper is I was a lot of it was designed as I went.

New ARM board. Ok, mostly this is because I accidently fried a not-so cheap piece of hardware :( but it gave me a good reason to update to an TS7400 board from www.embeddedarm.com. Nice features of this are that it is smaller and has an SD slot so I can easily have 2G of flash space. I also can boot from the SD card so I can have a full linux distro installed. I am using debian right now since an ARM image of debian was already available. I am normally a Fedora user and I hear some people are working on an ARM port of Fedora so I might go with that later on.

New Flame sensors!!! This is something I have been planning on designing for a long time and should make things much cleaner and more reliable. The picture here isn't so good. I will see about uploading a better pic later on. This is a small board with an i2c A/D converter on it and 4 IR phototransistors. I have used the phototransistors on my last few robots and they are simply _by_far_ the best way I have found to find the candle. Perhaps I am giving away one of my competitive advantages but I believe in sharing of info :)

New Flame sensors!!! This is something I have been planning on designing for a long time and should make things much cleaner and more reliable. The picture here isn't so good. I will see about uploading a better pic later on. This is a small board with an i2c A/D converter on it and 4 IR phototransistors. I have used the phototransistors on my last few robots and they are simply _by_far_ the best way I have found to find the candle. Perhaps I am giving away one of my competitive advantages but I believe in sharing of info :)The IR phototransistors can be bought from digikey for something like $0.75 each and are part number op599a. You don't need a fancy board like I designed. Use a 47k pull up resistor on one side and put the other side to ground. Connect one of your microcontroller's A/D ports between the resistor and the phototransistor. Works perfectly. It can be fooled a little by incandescent light bulbs or bright sunlight but if it is shaded from above I have found that isn't a problem. Also, does not get fooled at all by florescent lights or the sodum vapor lights used in the gym at Trinity.

I am considering starting a small (very small) home business and selling these boards. Probably not for any real profit but hopefully enough to offset my robot building costs. If people have an interest please post a comment here. I am guessing I could sell them in kit form for probably $25 each. However since the chip is a surface mount I imagine that would scare off many hobbyists. I might sell assembled boards for probably $45 each (need to figure out how much it is worth to me to solder a bunch of these myself).

For those of you going to the contest at Trinity come check them out and we can all see how well they really work.

Friday, February 8, 2008

Back home again

After 30 hours door to door I am back home again. Who knew Australia was so far away :)

For those of you who saw my presentation at LCA my slides are now up on the web page. There are a couple of slides I didn't bother showing during the talk which has references to software and hardware I used on Rockhopper. It can be found on the LCA page at: http://linux.conf.au/programme/thursday

I had a wonderful time at LCA and honestly it was worth the long trip. I spent a couple of days more in Melbourne. Of course this meant I was there for the superbowl which I was a bit concerned that I would miss it. I wasn't sure I could find anywhere showing it in Australia. Boy was I surprised! I checked a couple of sports bars but none said they would be open that early (since the game was shown live it was on at 10 am there). I was told the best bet would be the crown casino. I expected to find just a few American's there begging the bartender to turn it on to "that american football game". What I found was a large sports bar with probably 200 very excited football fans. While there met some really fun Australian fans and of course a few Americans spending some time abroad. So, I want to give a special G'day to Gary (aka Gazz), Rod, and Jamie from down under and Melody (from the US) and of course "guy from California" who I am ashamed I cannot remember your name.

Even though the Pats lost it was a hell of a game and I had more fun watching it than any superbowl I can remember.

So, now that I am back home I am already starting to think about possibly building a new bot for this year's contest at Trinity College. I have just about 2 months to work on it and this year I certainly won't be able to take a bunch of time off like last year. Still undecided but I am considering it.

For those of you who saw my presentation at LCA my slides are now up on the web page. There are a couple of slides I didn't bother showing during the talk which has references to software and hardware I used on Rockhopper. It can be found on the LCA page at: http://linux.conf.au/programme/thursday

I had a wonderful time at LCA and honestly it was worth the long trip. I spent a couple of days more in Melbourne. Of course this meant I was there for the superbowl which I was a bit concerned that I would miss it. I wasn't sure I could find anywhere showing it in Australia. Boy was I surprised! I checked a couple of sports bars but none said they would be open that early (since the game was shown live it was on at 10 am there). I was told the best bet would be the crown casino. I expected to find just a few American's there begging the bartender to turn it on to "that american football game". What I found was a large sports bar with probably 200 very excited football fans. While there met some really fun Australian fans and of course a few Americans spending some time abroad. So, I want to give a special G'day to Gary (aka Gazz), Rod, and Jamie from down under and Melody (from the US) and of course "guy from California" who I am ashamed I cannot remember your name.

Even though the Pats lost it was a hell of a game and I had more fun watching it than any superbowl I can remember.

So, now that I am back home I am already starting to think about possibly building a new bot for this year's contest at Trinity College. I have just about 2 months to work on it and this year I certainly won't be able to take a bunch of time off like last year. Still undecided but I am considering it.

Friday, February 1, 2008

Greetings from down under!

Yes, I am a horrible blogger. I have not updated the blog since the contest and yes I am quite ashamed of myself.

So certainly time for an update. I am writing this update from a hotel in Melbourne Australia where I am attending Linux Conf Australia. My manager urged me to submit a proposal to do a talk about Rockhopper to LCA a few months ago which got accepted. It is pretty cool that HP sent me here to talk about something that was not HP related (although I did talk about a lot of HP specific stuff with various people during the week).

The talk itself went very well and was voted one of the best in the conference. I was asked to do an encore of the talk today during what they call "Open Day" where members of the public can attend. I didn't think today's talk went quite as well as the first one but still not bad. The best part of the talk was the demo of the robot itself. I was not able to bring the robot itself but what I did do was set up a webcam in my workshop and run live streaming video. When I came up with that plan I gave it a 50/50 chance of actually working (it is from the other side of the world after all) but it worked perfectly. Special thanks to Paul for helping out on the New Hampshire end. He powered up the robot and lit the candles and most importantly he was there in case I ran into network issues (luckily there were none).

I plan on posting my slides and code for the robot online soon (yes, should have done that months ago). Hopefully that will happen in a week or so. I am staying a couple more days in Melbourne to do the tourist thing (have not done anything but the conference since I got here).

The video of my talk can be found on the LCA web site.

So certainly time for an update. I am writing this update from a hotel in Melbourne Australia where I am attending Linux Conf Australia. My manager urged me to submit a proposal to do a talk about Rockhopper to LCA a few months ago which got accepted. It is pretty cool that HP sent me here to talk about something that was not HP related (although I did talk about a lot of HP specific stuff with various people during the week).

The talk itself went very well and was voted one of the best in the conference. I was asked to do an encore of the talk today during what they call "Open Day" where members of the public can attend. I didn't think today's talk went quite as well as the first one but still not bad. The best part of the talk was the demo of the robot itself. I was not able to bring the robot itself but what I did do was set up a webcam in my workshop and run live streaming video. When I came up with that plan I gave it a 50/50 chance of actually working (it is from the other side of the world after all) but it worked perfectly. Special thanks to Paul for helping out on the New Hampshire end. He powered up the robot and lit the candles and most importantly he was there in case I ran into network issues (luckily there were none).

I plan on posting my slides and code for the robot online soon (yes, should have done that months ago). Hopefully that will happen in a week or so. I am staying a couple more days in Melbourne to do the tourist thing (have not done anything but the conference since I got here).

The video of my talk can be found on the LCA web site.

Sunday, April 15, 2007

Rockhopper wins first place in Expert division!

Needless to say I am rather happy with the result! The contest consisted of 3 runs. On each run there are a total of 4 tasks worth one point each. The tasks are: put out the candle in the lower level of the maze, put out the candle on the upper level, find and mark the "baby" and go up and down the ramp between floors. I was not able to find the baby on any of the runs (the first run it actually did find the baby but dropped the beacon in the hallway outside of the room instead of in the room) put out the candle and made it up and down the ramp (total of 2 points). On my 2nd and 3rd runs it put out both candles and made it up and down the ramp on each for 3 points on each run. My total came to 8 points, the 2nd place robot only scored 2, 3rd place put out one candle for 1 point.

The thing that gave me the edge was reliability. I kept my navigation code very simple (in fact so simple I hesitate to call it "navigation"). I had done a _lot_ of testing ahead of time and tried to make sure it was able to handle any situation without getting stuck. At one point it did manage to get partially wedged against a wall but it _knew_ it was stuck and was able to get free (after 15 or 20 seconds of spinning it's wheels). Other than that my biggest issue was since it doesn't have any real sort of navigation or knowledge of where it is located in the maze it often went into the same room multiple times while missing other rooms entirely. I made some small tweaks (ok, hacks really) to the code between runs and improved it a bit.

The competition was a lot of fun. I enjoyed meeting several of the other robot builders. I had several people ask me a lot of questions about the robot which I really enjoyed. Hopefully people learned some new things from talking to me, I know I learned a few new things from talking to the other builders as well.

I plan on still making a few more updated to the blog with what I have learned over the past couple of months and also some thoughts for the future. I do however need to get back to working on our kitchen before Jane shoots me! So no more robot projects for a little while but I will get back to it! I am thinking I will likely do the competition at Trinity next year but after that I am thinking robot soccer would be a new and interesting challenge.

One last note. For those of you how have followed along and are getting the robot building bug I highly recommend the competition at Trinity. They have entry level divisions for younger builders as well as 2 different high school divisions and a "senior" division open to college students or individual hobbyists. And of course the expert division if you want to run your robot against Rockhopper II next year!

Saturday, April 14, 2007

Greetings from Hartford

The big weekend is finally here. Jane and I are in Hartford for the weekend for the Trinity College robot competition. So the robot is officially "done". Of course by "done" I mean I am out of time! There are still a lot of things I would like to do, mostly on the software end but I am still fairly happy with what I have. The robot is able to get around the maze without getting stuck. It is able to put the candle out nearly all of the time, the only "glitch" here is sometimes it bumps into the candle before it sees it. I can find the "baby" somewhat reliably although that hasn't been tested quite as much.

The biggest thing I wasn't able to get to is some sort of mapping software so that it has some concept of where it is at. It is pretty simple navigation code at this point. It simply follows the left wall then after a certain amount of time (which can be configured at compile time) it switches to following the opposite wall. Hopefully this will be enough to prevent it getting stuck in a loop. Unlike previous years they are not going to reconfigure the maze between runs so I hopefully can look at the layout early in the day and make any needed changes.

I am told there are a total of 10 robots entered in the "expert" division. I talked with 3 or 4 of the other "expert" division builders today. It sounds like most of them made the typical mistake of making things too complex and leaving too much to do toward the end. My robot was the only one I saw actually moving about reliably in the maze so it is looking good as long as nothing breaks (knocking on wood as I type of course).

They usually post results on the web page later in the day after the competition if any of you are curious to see how I did. I will certainly add a new post here but likely not until Monday and since that is my last day before going back to work I will probably sleep late!

The biggest thing I wasn't able to get to is some sort of mapping software so that it has some concept of where it is at. It is pretty simple navigation code at this point. It simply follows the left wall then after a certain amount of time (which can be configured at compile time) it switches to following the opposite wall. Hopefully this will be enough to prevent it getting stuck in a loop. Unlike previous years they are not going to reconfigure the maze between runs so I hopefully can look at the layout early in the day and make any needed changes.

I am told there are a total of 10 robots entered in the "expert" division. I talked with 3 or 4 of the other "expert" division builders today. It sounds like most of them made the typical mistake of making things too complex and leaving too much to do toward the end. My robot was the only one I saw actually moving about reliably in the maze so it is looking good as long as nothing breaks (knocking on wood as I type of course).

They usually post results on the web page later in the day after the competition if any of you are curious to see how I did. I will certainly add a new post here but likely not until Monday and since that is my last day before going back to work I will probably sleep late!

Monday, April 9, 2007

The final week!

It is crunch time now. I am down to less than a week to go before the contest. Sorry I have not been good about posting lately. Rockhopper is completely built now (or as built as it is going to be). Building the bot itself and getting the low-level programming done and working took longer than expected (i.e. see my last post about the i2c performance issue). So, it looks like once again I don't have much time left to do the interesting high-level AI programming I wanted to do. I do however have it working fairly well now. It can detect and put out the candle without much trouble. It can also do a fairly good job of not getting stuck in the maze. I was having some trouble where it would run into the corner of a wall if it was in the blind spot of my ir range sensors and sometimes the bumper switches would not trigger so it would just keep pushing against the wall (very bad). I added some code to check the wheel speed based on the wheel encoders so now when the rpm of the wheels drops it knows it is stuck. This seems to be working nicely now.

I also built a beeper used to mark where the "baby" is in the maze. The "baby" is a 15 watt light bulb painted black. When the robot finds this it is supposed to drop a beeper that beeps 2 times per second. I am really happy with my solution for how I drop the beeper. I will try to take pictures of it if I get a chance. Basically it is just a motor on a hinge with a small rubber wheel on it. The wight of the motor holds the beeper in place then when the motor is turned on, the wheel spins the beeper off. This also releases the switch on the beeper which turns it on. This all works better than expected. I now need to work on my code for finding the baby itself. I plan on doing that later today.

What I have been working on the last couple of days is trying to use a neural network to interpret the sonar data. I hope that this will help filter out the false pings you commonly get with sonars. So far I am not having much luck but I have found a few critical errors in my code. I wrote the original code late at night long after I should have gone to bed so it isn't as clean as I would like. If I don't get it working somewhat well by lunchtime today I am going to scrap the neural net idea and write some simple code that uses the raw data. It will be more likely to do strange things because of false pings but at this point I am running out of time!

So, looks like I can certainly do the task of the competition but not as well as I would like. Probably the biggest thing that I need that I have done no work on is somewhat to know if it is just doing circles in the maze and not actually exploring new areas. If I get my sonars and the "baby" detection stuff working that will be my next task.

Next Tuesday I go back to work. I really am enjoying my time off but it will be nice to get back to a 5 day work week! I have been averaging about 10 hours a day 7 days a week on this.

I also built a beeper used to mark where the "baby" is in the maze. The "baby" is a 15 watt light bulb painted black. When the robot finds this it is supposed to drop a beeper that beeps 2 times per second. I am really happy with my solution for how I drop the beeper. I will try to take pictures of it if I get a chance. Basically it is just a motor on a hinge with a small rubber wheel on it. The wight of the motor holds the beeper in place then when the motor is turned on, the wheel spins the beeper off. This also releases the switch on the beeper which turns it on. This all works better than expected. I now need to work on my code for finding the baby itself. I plan on doing that later today.

What I have been working on the last couple of days is trying to use a neural network to interpret the sonar data. I hope that this will help filter out the false pings you commonly get with sonars. So far I am not having much luck but I have found a few critical errors in my code. I wrote the original code late at night long after I should have gone to bed so it isn't as clean as I would like. If I don't get it working somewhat well by lunchtime today I am going to scrap the neural net idea and write some simple code that uses the raw data. It will be more likely to do strange things because of false pings but at this point I am running out of time!

So, looks like I can certainly do the task of the competition but not as well as I would like. Probably the biggest thing that I need that I have done no work on is somewhat to know if it is just doing circles in the maze and not actually exploring new areas. If I get my sonars and the "baby" detection stuff working that will be my next task.

Next Tuesday I go back to work. I really am enjoying my time off but it will be nice to get back to a 5 day work week! I have been averaging about 10 hours a day 7 days a week on this.

Tuesday, March 27, 2007

The joy of performance bugs

I just realized it has been over a week since my last post. It has been a very busy week. I was able to get a lot of the old code ported (well more like re-written using the original code as a rough guide). It was able to navigate the maze and do decent obstacle avoidance. This all still needs a bit of work but it usable for now. I want to get all the critical bits working at an acceptable level before I work on perfecting all of the code.

I then built my flame sensors which took a bit of time but no real surprises. I took some pics of the sensors but my wife borrowed the camera and I have not gotten around to downloading the photos off of it.

The "fun" part started when I added code to talk to the flame sensors. The sensors are connected directly to a couple of AVR ATMEGA32 microcontrollers (the ones I designed the boards for which I posted about a few weeks back). Then the ARM (which is my main processors running Linux) talks to the AVR using the i2c protocol. When I added this code I ran into some serious latency issues which slowed things down to the point where the robot would constantly hit walls and not be able to navigate at all. I had done some calculations based on the speed of the i2c bus and had figured that it would have been able to read the sensor data many times over with no problems. In reality this obviously wasn't the case.

I was able to get the "oprofile" tool cross compiled for the ARM so I could gather some data to see where it was spending the most time. The data showed that over 20% of the time was being spent inside the i2c driver. Keep in mind that this ARM board does not actually have an i2c device so I am using the i2c "bit bang" driver which implements the driver in software using a couple of general purpose i/o pins. Still it should not have been eating up as much time as it did.

After a _lot_ of debugging and experimenting I came to the realization that the real bottleneck was the AVR was holding the clock line low (which is used in the protocol as a way to let the master device know that the slave device is not yet ready). I also realized that the Linux bit-bang i2c driver doesn't block in this situation (at least not when running with kernel preemption disabled as is the default for ARM). So, the ARM was wasting time spinning while waiting for the clock line to get released.

So I got a chance to learn some more Linux kernel internals! This of course was one of my goals for this project. I was able to modify the code so that it would block if the clock line was being held low and I also added an interrupt handler so that it could wake up when the line was then released.

This didn't _quite_ fix it. My code is made up of multiple threads, each of which implements a different behavior of the robot. Since the thread that was looking at the flame sensors was constantly getting blocked on interrupts the Linux scheduler essentially increased it's priority since it is then an "interactive" thread. This is the same functionality that allows your text editor to remain responsive even when someone else is running another process that is compute bound (i.e. a database). This part I knew how to fix using some pthreads scheduler magic. In the process of fixing this I implemented some other thread related optimizations I had been considering.

I now have the robot being able to navigate the maze with no critical issues (it bumps walls on occasion but not excessively) and is able to find and blow out the candle. None of this is perfect yet as I mentioned but it does work.

My next goal is to get the audio start working. For the "expert" division of the contest you are required to start the robot using a tone that is supposed to simulate a smoke detector going off. I have a few schematics for circuits to do this and I have all the parts but this is one of the analog electronics things I am not all that comfortable with. Hopefully I can get this working without any more big delays. According to the schedule I put together before I started I am 2 weeks behind. Obviously I won't be able to do everything I wanted to do. My schedule did have a full 2 weeks at the end for nothing but debug time so it sounds like that is what I will loose. I guess I just can't allow myself to have any bugs in my code ;)

I then built my flame sensors which took a bit of time but no real surprises. I took some pics of the sensors but my wife borrowed the camera and I have not gotten around to downloading the photos off of it.

The "fun" part started when I added code to talk to the flame sensors. The sensors are connected directly to a couple of AVR ATMEGA32 microcontrollers (the ones I designed the boards for which I posted about a few weeks back). Then the ARM (which is my main processors running Linux) talks to the AVR using the i2c protocol. When I added this code I ran into some serious latency issues which slowed things down to the point where the robot would constantly hit walls and not be able to navigate at all. I had done some calculations based on the speed of the i2c bus and had figured that it would have been able to read the sensor data many times over with no problems. In reality this obviously wasn't the case.

I was able to get the "oprofile" tool cross compiled for the ARM so I could gather some data to see where it was spending the most time. The data showed that over 20% of the time was being spent inside the i2c driver. Keep in mind that this ARM board does not actually have an i2c device so I am using the i2c "bit bang" driver which implements the driver in software using a couple of general purpose i/o pins. Still it should not have been eating up as much time as it did.

After a _lot_ of debugging and experimenting I came to the realization that the real bottleneck was the AVR was holding the clock line low (which is used in the protocol as a way to let the master device know that the slave device is not yet ready). I also realized that the Linux bit-bang i2c driver doesn't block in this situation (at least not when running with kernel preemption disabled as is the default for ARM). So, the ARM was wasting time spinning while waiting for the clock line to get released.

So I got a chance to learn some more Linux kernel internals! This of course was one of my goals for this project. I was able to modify the code so that it would block if the clock line was being held low and I also added an interrupt handler so that it could wake up when the line was then released.

This didn't _quite_ fix it. My code is made up of multiple threads, each of which implements a different behavior of the robot. Since the thread that was looking at the flame sensors was constantly getting blocked on interrupts the Linux scheduler essentially increased it's priority since it is then an "interactive" thread. This is the same functionality that allows your text editor to remain responsive even when someone else is running another process that is compute bound (i.e. a database). This part I knew how to fix using some pthreads scheduler magic. In the process of fixing this I implemented some other thread related optimizations I had been considering.

I now have the robot being able to navigate the maze with no critical issues (it bumps walls on occasion but not excessively) and is able to find and blow out the candle. None of this is perfect yet as I mentioned but it does work.

My next goal is to get the audio start working. For the "expert" division of the contest you are required to start the robot using a tone that is supposed to simulate a smoke detector going off. I have a few schematics for circuits to do this and I have all the parts but this is one of the analog electronics things I am not all that comfortable with. Hopefully I can get this working without any more big delays. According to the schedule I put together before I started I am 2 weeks behind. Obviously I won't be able to do everything I wanted to do. My schedule did have a full 2 weeks at the end for nothing but debug time so it sounds like that is what I will loose. I guess I just can't allow myself to have any bugs in my code ;)

Sunday, March 18, 2007

halfway point report

I am now at the halfway point through my sabbatical and Rockhopper is starting to look somewhat complete as far as the building part of it goes. Now I can start getting serious with writing code. I have spent the last few days with getting the bumper build and installed (along with switches to tell the CPU if it has hit something), fixing up and organizing the wiring and writing a Linux device driver to send the PWM signal to to the motors to control speed.

The first real usable user-space program I wrote was a simple bit of code that allowed me to log in remotely and drive the robot around with keyboard commands. I was surprised at how fast it moves with 12V batteries. I won't be driving the motors at full speed much. I considered just running them at 6V but I want the full 12V to power the fan to blow out the candle. I might be able to run it at full speeds down hallways when the sonars and IR rangefinders both say all is clear but at the speeds it moves it rolls so far after a STOP command that it will likely just crash a lot. I can do active breaking with the motors however I am concerned about how much stress that puts on the motor's gears.

I then wrote a short program to wander around and turn if it sees something close using the ir range finding sensors. This is Rockhopper's first bit of autonomous programming! I set up some boards as boundaries and let it roam about for a while. This pic below shows it happily roaming about.

My next plan is to take the code for roaming about the maze I wrote for my last robot (Fawkes) and port it over. It was written in Java and Rockhopper's code is in C but I am mostly interested in the algorithms I used. Fawkes was able to follow the maze completely flawlessly so that should be a good starting point. Once I get it working farily well I will incorporate the sonar sensor inputs for redundancy.

My next plan is to take the code for roaming about the maze I wrote for my last robot (Fawkes) and port it over. It was written in Java and Rockhopper's code is in C but I am mostly interested in the algorithms I used. Fawkes was able to follow the maze completely flawlessly so that should be a good starting point. Once I get it working farily well I will incorporate the sonar sensor inputs for redundancy.

Wednesday, March 14, 2007

Rockhopper takes it's first baby steps!

I feel like a proud papa. At around 11:00 AM today Rockhopper took it's first steps. I don't have any sensors hooked up yet but I wrote a quickie program to just turn the motors on for 5 seconds and go straight and it moved across the floor for a few feet completely under battery power and while I was logged in via ssh over the wireless net. I do have one minor bug where it doesn't turn both motors on at the same time. I have some "optimization" code in the motor routine that prevents it from doing anything if the speed has not changed, I think I have a bug there. Shouldn't be too tricky. Once I have that fixed I am going to write a program to drive it around via keyboard commands.

So far I am very happy with how long it runs on the battery. I had it booted with wireless ethernet for over an hour last night on a battery pack that wasn't even fully charged. Granted that was without any sensors and I expect the IR rangefinders will pull a bit of current but this is very promising.

So far I am very happy with how long it runs on the battery. I had it booted with wireless ethernet for over an hour last night on a battery pack that wasn't even fully charged. Granted that was without any sensors and I expect the IR rangefinders will pull a bit of current but this is very promising.

Tuesday, March 13, 2007

[technical stuff] packed full of electronics goodness!

I spend the day doing more wiring and creating a couple of simple boards "the old fashioned way". One is a breakout board that gives me easy connection to power, ground and signal wires for analog sensors. The other is a board that allows me to connect 3.3V (i.e. my ARM board) and 5V hardware on the same i2c bus. The documentation for the ARM had many very serious warnings about not driving any of the pins above 3.3V. Since this wasn't cheap I figured I should listen!

I now have nearly everything that will go inside the base installed. My planning paid off. I really don't think I would have been able to fit everything in if I had not spend the time planning out the base.

The plan for tomorrow is to write a Linux device driver for the A/D converter board on the ARM and if I get that done I want to put together a library of routines so I can start writing some actual robot code.

I am still way behind schedule but moving forward.

My AVR boards are in

The FedEx guy just delivered my custom designed AVR boards! They look good so far. Hopefully I won't find any surprises when I assemble them and test them out. This was kind of a rush job because I realized I needed them just before we went on the cruise. I needed to get the design sent out before we left so I wouldn't get delayed.

The FedEx guy just delivered my custom designed AVR boards! They look good so far. Hopefully I won't find any surprises when I assemble them and test them out. This was kind of a rush job because I realized I needed them just before we went on the cruise. I needed to get the design sent out before we left so I wouldn't get delayed.I plan on using 3 of these. Mostly they will be used to add additional analog inputs (each has 8 inputs). Two of them will be connected to 8 IR phototransistors which I will use to find the candle. My last robot used the same sensors however I had only 5 free inputs. I will have 2 sets of 8 of these, each in a radial pattern. I will have one set on the left side and one on the right. This should allow me to determine the distance as well as direction to the flame.

I have spent the last couple of days working on wiring and getting more electronics installed. This has been time consuming and tedious but I know from past experience that if I don't do a neat and tidy job here it will cause lots of issues later. I really thought I would have something functional by now but everything seems to take longer than I expected. I have just under 5 weeks left. I know I will have something working by then but I may not be able to do as much as I dreamed of.

Sunday, March 11, 2007

Starting to look like something!

Assembly of the base didn't go quite as smoothly as I had hoped for. I ended up having to re-make a few of the parts. I am however happy with the results (but not happy with the amount of time it has taken to get this far). I got all of the parts for the base assembled yesterday. Today I have been working on getting the electronics and wiring installed.

So far I have the motors, motor driver, 5V regulator and the ARM board installed. I added an external RJ45 ethernet jack for the network (the wired net will be just used for development and debugging, will use wireless for the actually running) and an external DB9 port so I can get to the console. I also added 2 switches to the top. One will control the power to the 5V regulator so I can shut off all the electronics and the other will just kill the power to the motors. I plan on running 3 battery packs. A 9.6V RC car battery pack will power the electronics and 2 - 6V packs wired in serial to give 12V will power the motors. I should be able to have plenty of runtime. The time limit on each round of the competition is something like 5 minutes however I am more concerned about long runtimes when doing debugging.

I discovered today that I ordered the wrong connectors to connect to the batteries. Radio Shack sells them (however they are a bit overpriced) so I will pick up a couple tomorrow. I did have one of the right type on hand so I used that to connect the 5V regulator to the battery. None of my batteries are charged right now but I hope to be able to power the ARM up on battery power in the morning. I think I am done for today. Been a long day and I should probably spend some time with my wife before she forgets who I am!

Getting closer to having something that can roam about under it's own power. I thought I would be there by now but keep hitting snags and having to redesign parts. I still think time spent now will pay off in the end.

Friday, March 9, 2007

Parts Parts Parts!

I realize I have been bad this week about posting updates. I spent the week making parts out of PVC. Honestly much more time was spent designing, cutting pieces and then redesigning. This took longer than I expected (which puts me even farther behind schedule) but I wanted to be sure I have all of this working they way I want. Otherwise it will likely cause more delays later. My goal it to have interchangeable parts that I can easily make duplicates of. So far I have made enough parts for 2 bots. I plan on building 2 both so I have a backup and also because the expert division of the competition allows for cooperating robot swarms so I do plan on using both at the same time if all goes well.

I made the wheels out of 1/2 PVC sheet and silicone. The silicone is sold as mold making material for casting flexible molds which can be used to cast plastic parts. It comes as a liquid with a hardener. This is the first I have used it but it was easy to work with and turned out great. For those interested it is HobbyMold 150. I made a form out of larger PVC pipe which I cut into 3 sections (to allow it to be removed from the final part) and drilled shallow holes with a unibit to create the tread pattern. I am very happy with the result. So far I have only made 1 pair of wheels but most of the time was spend designing the form so making another pair won't take long. It takes about 24 hours for the silicone to cure but not much effort needed at this point.

I made the wheels out of 1/2 PVC sheet and silicone. The silicone is sold as mold making material for casting flexible molds which can be used to cast plastic parts. It comes as a liquid with a hardener. This is the first I have used it but it was easy to work with and turned out great. For those interested it is HobbyMold 150. I made a form out of larger PVC pipe which I cut into 3 sections (to allow it to be removed from the final part) and drilled shallow holes with a unibit to create the tread pattern. I am very happy with the result. So far I have only made 1 pair of wheels but most of the time was spend designing the form so making another pair won't take long. It takes about 24 hours for the silicone to cure but not much effort needed at this point.

I have all but 2 minor pieces needed to make the base of the robot. This is where most of my week was spent. Each robot is made up of 18 PVC pieces (not counting the wheels). I designed it so that it should go together like a kit. We will see tomorrow when I actually start assembling the first robot.

I have all but 2 minor pieces needed to make the base of the robot. This is where most of my week was spent. Each robot is made up of 18 PVC pieces (not counting the wheels). I designed it so that it should go together like a kit. We will see tomorrow when I actually start assembling the first robot.

Once I was satisfied with the design of each piece I used xfig (a nice simple UNIX drawing program) to draw each part up and print out a template. I then stuck the template onto the PVC sheet using an elmers glue stick. This made drilling holes go fairly quickly. I bought a new drill press a while back that has a laser sight which puts an X right where the hole will go. This made life much nicer. My old drill press didn't have that and it also had a bit of a wobble making accurate holes nearly impossible.

I will put it all together tomorrow. I will take a pic an post it. I should have enough of the electronics mounted to make it move about on its own by the end of the weekend!

I made the wheels out of 1/2 PVC sheet and silicone. The silicone is sold as mold making material for casting flexible molds which can be used to cast plastic parts. It comes as a liquid with a hardener. This is the first I have used it but it was easy to work with and turned out great. For those interested it is HobbyMold 150. I made a form out of larger PVC pipe which I cut into 3 sections (to allow it to be removed from the final part) and drilled shallow holes with a unibit to create the tread pattern. I am very happy with the result. So far I have only made 1 pair of wheels but most of the time was spend designing the form so making another pair won't take long. It takes about 24 hours for the silicone to cure but not much effort needed at this point.

I made the wheels out of 1/2 PVC sheet and silicone. The silicone is sold as mold making material for casting flexible molds which can be used to cast plastic parts. It comes as a liquid with a hardener. This is the first I have used it but it was easy to work with and turned out great. For those interested it is HobbyMold 150. I made a form out of larger PVC pipe which I cut into 3 sections (to allow it to be removed from the final part) and drilled shallow holes with a unibit to create the tread pattern. I am very happy with the result. So far I have only made 1 pair of wheels but most of the time was spend designing the form so making another pair won't take long. It takes about 24 hours for the silicone to cure but not much effort needed at this point. I have all but 2 minor pieces needed to make the base of the robot. This is where most of my week was spent. Each robot is made up of 18 PVC pieces (not counting the wheels). I designed it so that it should go together like a kit. We will see tomorrow when I actually start assembling the first robot.

I have all but 2 minor pieces needed to make the base of the robot. This is where most of my week was spent. Each robot is made up of 18 PVC pieces (not counting the wheels). I designed it so that it should go together like a kit. We will see tomorrow when I actually start assembling the first robot.Once I was satisfied with the design of each piece I used xfig (a nice simple UNIX drawing program) to draw each part up and print out a template. I then stuck the template onto the PVC sheet using an elmers glue stick. This made drilling holes go fairly quickly. I bought a new drill press a while back that has a laser sight which puts an X right where the hole will go. This made life much nicer. My old drill press didn't have that and it also had a bit of a wobble making accurate holes nearly impossible.

I will put it all together tomorrow. I will take a pic an post it. I should have enough of the electronics mounted to make it move about on its own by the end of the weekend!

Wednesday, March 7, 2007

Back in cold New Hampshire

New Hampshire is cold this time of year. It seems even colder when you spend the past week on a ship in 85 degree weather! The vacation was very nice. I didn't take a lot of pictures but I am posting a few here. The first two here are Jane and myself each standing in front of the ship in

New Hampshire is cold this time of year. It seems even colder when you spend the past week on a ship in 85 degree weather! The vacation was very nice. I didn't take a lot of pictures but I am posting a few here. The first two here are Jane and myself each standing in front of the ship in  Freeport Bahamas. We didn't do much in Freeport, just wandered around and walked on the beach for a bit.

Freeport Bahamas. We didn't do much in Freeport, just wandered around and walked on the beach for a bit.The second stop for the ship was Grand Caymen. I forgot the camera on the ship so no pics from there. We found a nice outdoor restaurant/bar right on the water where Jane went snorkeling while I had a couple of beers. Fun for the whole family!

The last stop was _supposed_ to be Costa Maya Mexico however the above picture is as close as we got. High winds and 8ft waves made it too dangerous to dock there. The ship you see in the picture got in earlier in the day before the winds got too high. We heard they were stuck there for a couple of days.

So, what did we spend most of our time doing on the trip? The picture below sums it up pretty well. Yes, we are wild and crazy party people!

Friday, February 23, 2007

To the caribbean!

Thursday, February 22, 2007

[technical stuff] my atmega32 PCB design

Been a very busy day! I plan on using some AVR ATMega32 microcontrollers as a cheap and easy way to add some A/D converters which can do their own averaging / filtering of analog signals. Last night as I was experimenting with the smaller ATMega8 I quickly came to the realization that things would go MUCH more smoothly if I had some PCBs fabed for these (so I don't have wires running everywhere). Since we are leaving Saturday for our cruise I need to get this sent out for manufacturing TODAY!

Now I am far from a hardware expert. I have only designed 1 board before and that was several years ago (and was a much simpler board). Luckily there is some good software for this. Eagle CAD from CadSoft runs on Linux and has a free version which has all the capabilities I need. It took me about 1/2 the day just to learn the software, 1/2 the day to design the board, and 1/2 the day to figure out how to generate the files needed by the manufacturer (yes, that is 3/2, like I said it was a busy day!).

Tomorrow I plan on putting together a digikey order so the last of my components should be here when I get back. The boards have a 10 day lead time (which is why it was critical to get that in now). That will give me a week when we get back for working on the mechanical parts of the bot. So for I _think_ I have things planned out so that I won't waste any time waiting on parts!

Monday, February 19, 2007

[technical stuff] The hard drive saga

I ran into a few snags over this weekend. My goal on Saturday was to get the sonar hooked up so I could experiment with it. I put together a distribution board that I can use to connect multiple i2c devices onto the bus and added a couple resisters to pull the data lines high. Then I went to my workbench computer (an old G3 mac running ubuntu linux) and it crashed! After attempting to reboot I found that it was complaining about bad sectors on the hard drive. Oh well, it is an old computer and all of my critical data is on my newer desktop system. Since it appeared to be just the drive I figured it would be worthwhile to just get a new drive for it. After booting from CD I was able to do an fsck (after several tries) and mount the disk read-only. I backed the data up over the network and called it a day (had a party to go to that night).

I picked up a new 320GB drive and installed it sunday. I made several unsuccessful attempts to install ubuntu to it, fiddled with connections, tried various methods of partitioning the drive, none of which worked. I was starting to suspect the new drive was bad but then did some research. Turns out the IDE controller on the old G3 mac has a maximum of somewhere around 130GB!!!! I was frustrated but at least I understood the problem. I had been wanting to add another drive to my newer system to allow me to do backups. The drive worked just fine there.

So, after nearly 2 days of fiddling (and yes a little slacking off I admit, it was the weekend!) my workbench system was still down. Since the drive seemed happy after the fsck and the data was then backed up I went ahead and put it back in. It seems to be working ok at the moment but I plan on buying a new (under 130GB of course) drive and replacing it soon.

Today (monday) I finally got back to experimenting with the sonar. I was using the linux kernel's i2c "bit bang" code along with my own driver for the digital I/O board from technologic systems for this. I was not able to get the sonar device to send the ack's when it is addressed on the bus. I decided to back up and write some user-space code to implement at least a minimal subset of i2c. With a lot of technical specs, example code, and most importantly my logic analyzer I was able to get it working. The code is a bit of an ugly hack for now but I can use what I learned from this to make the kernel driver work. I imagine it is something simple.

Tomorrow I plan on experimenting with my AVR microcontrollers and and make sure I can communicate with them over the i2c bus as well.

I picked up a new 320GB drive and installed it sunday. I made several unsuccessful attempts to install ubuntu to it, fiddled with connections, tried various methods of partitioning the drive, none of which worked. I was starting to suspect the new drive was bad but then did some research. Turns out the IDE controller on the old G3 mac has a maximum of somewhere around 130GB!!!! I was frustrated but at least I understood the problem. I had been wanting to add another drive to my newer system to allow me to do backups. The drive worked just fine there.

So, after nearly 2 days of fiddling (and yes a little slacking off I admit, it was the weekend!) my workbench system was still down. Since the drive seemed happy after the fsck and the data was then backed up I went ahead and put it back in. It seems to be working ok at the moment but I plan on buying a new (under 130GB of course) drive and replacing it soon.

Today (monday) I finally got back to experimenting with the sonar. I was using the linux kernel's i2c "bit bang" code along with my own driver for the digital I/O board from technologic systems for this. I was not able to get the sonar device to send the ack's when it is addressed on the bus. I decided to back up and write some user-space code to implement at least a minimal subset of i2c. With a lot of technical specs, example code, and most importantly my logic analyzer I was able to get it working. The code is a bit of an ugly hack for now but I can use what I learned from this to make the kernel driver work. I imagine it is something simple.

Tomorrow I plan on experimenting with my AVR microcontrollers and and make sure I can communicate with them over the i2c bus as well.

Saturday, February 17, 2007

My sabbatical has begun!

You may have noticed that I have not done many updates lately. That should change now that I am officially on sabbatical for the next 8 weeks! It sort of feels like summer vacation when I was a kid (except for the weather). It sounds like a lot of time but I will be busy getting rockhopper going. But don't worry, it won't be all hard work. Jane and I are taking a week long cruise leaving a week from today.

Ok, now more technical stuff...

I received a few more parts in the mail the other day. Most importantly my sonar units. I found some really nice units made by Devantech. I chose the SRF08 sonar because it should be easy to interface using an i2c bus and also because it has the ability to listen for multiple pings. I have not had the chance to do any work with sonar since college but what we found from experimenting back then was the first ping received is often not not always what you want. The plan is to take the data from 3 sonar units and feed that into a neural network. I will write up more on this later on. The plan for today is to just try to interface the sonar to my ARM board to make sure I can get readings.

I also ordered a digital compass, also from devantech. My first robot for the Trinity robot contest also used a compass. I found that while in a building such as the gymnasium at Trinity it will at first appear to give random readings. You can move in a straight line and have massive compass deflection. While this may appear random it _is_ consistent in a single location. I hope to be able to use this to help recognize locations inside the maze. The compass also interfaces using i2c.

Ok, now more technical stuff...

I received a few more parts in the mail the other day. Most importantly my sonar units. I found some really nice units made by Devantech. I chose the SRF08 sonar because it should be easy to interface using an i2c bus and also because it has the ability to listen for multiple pings. I have not had the chance to do any work with sonar since college but what we found from experimenting back then was the first ping received is often not not always what you want. The plan is to take the data from 3 sonar units and feed that into a neural network. I will write up more on this later on. The plan for today is to just try to interface the sonar to my ARM board to make sure I can get readings.

I also ordered a digital compass, also from devantech. My first robot for the Trinity robot contest also used a compass. I found that while in a building such as the gymnasium at Trinity it will at first appear to give random readings. You can move in a straight line and have massive compass deflection. While this may appear random it _is_ consistent in a single location. I hope to be able to use this to help recognize locations inside the maze. The compass also interfaces using i2c.

Sunday, February 4, 2007

[technical stuff] rockhopper gets a brain!

This is _not_ battlebots. While I enjoy robotic mayhem of two robots fighting to the death as much as anyone I find the challenge of autonomous robotics much more interesting. For the robot to be autonomous it of course needs some sort of CPU. My first Trinity competition robot from 2001 used 2 PIC microcontrollers for low level functions connected to a Palm for higher level processing. That worked fairly well however since it was all implemented on solderless breadboards it was less than reliable. It did however show me just how much you could do with a $5 PIC. My second entry from 2005 (Fawkes as shown in my first blog post) used a Motorola 68HC11 based "Handyboard" robot controller.

The most difficult part of these earlier robots was debugging the code. Since these run embedded code with no operating system there is little that can be done for debugging beyond printing short messages on an LCD or flashing an LED. I found myself spending most of my time making minor changes to the code, recompiling, downloading to the robot with a serial cable and trying again. So much time was spent on this that it did not leave time to write any complex AI code.

I needed something that could run a real OS. In my line of work there is only ONE choice here! There are several companies that make single board computers (SBC) using the ARM cpu that run Linux quite well. I made the choice to go with the TS7260 from Technologic Systems.

Basic specs:

- 200 MHz ARM cpu

- on board ethernet

- on board USB

- PC104 bus to allow for expansion options

- 64MB RAM

- 32MB Flash memory

The one downside of the Technologic Systems boards is they only support a 2.4 Linux kernel. With the help of others on the discussion group and a lot of digging I was able to cobble together a set of patches for the 2.6.20 kernel.

Tuesday, January 23, 2007

Why the name "rockhopper"?

Saturday, January 20, 2007

Initial post - Welcome!

Welcome to my blog! My plan is to use this to keep people up to date and to document the building of my entry for this years Trinity College Fire Fighting Home Robot contest. I plan on having a mix of non technical stuff for my "non geek" (and I use the word geek proudly) friends and family as well as some interesting technical details about the robot and it's design for my work friends at HP and Red Hat as well as other Linux and robotics enthusiasts.

Pictured above is my previous Trinity competition entry named "Fawkes" from 2005 (I did not find the time to enter in 2006). I added that picture because at this point there isn't much to photograph of my latest robot since I am still building it. I figured I needed something robot related for my first post.

I have high hopes for this years contest. This will be the first time I have been able to spend a large amount of time on a robotics project because I will be taking a 2 month sabbatical from HP (thanks Suzanne!). So from Feb 17th up until the contest on April 15th I will be out of work and focusing on "Rockhopper" (more on the significance of the name later). Before my sabbatical I plan on spending quite a bit of night and weekend time on it as well.

More to come....

Subscribe to:

Comments (Atom)